Atlas Copco Leverages AI to Enhance Industrial Operations

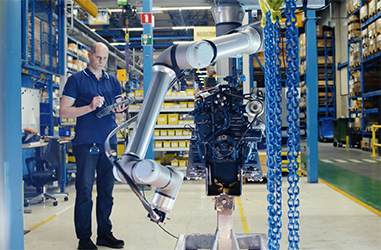

Atlas Copco is integrating artificial intelligence across its operations to drive innovation and efficiency in manufacturing and warehousing. In its Antwerp Product Company, the company uses AI-driven quality control systems to perform advanced visual inspections, minimizing waste and improving product reliability. Collaborative robots, or cobots, further enhance assembly processes by handling repetitive tasks, creating a safer and more dynamic work environment.

AI also underpins Atlas Copco’s warehousing operations, where smart management systems optimize inventory control to prevent overstocking or shortages. Additionally, AI-powered energy management solutions reflect the company’s commitment to sustainability by reducing energy consumption and environmental impact. These advancements are part of Atlas Copco’s broader digitalization strategy aimed at improving productivity, quality and operational efficiency.

The company states that its AI initiatives demonstrate how technology can complement human creativity and innovation. By combining advanced tools with skilled teams, Atlas Copco aims to set new standards for efficiency and sustainability in industrial operations.

For more information

Categories: Compressed Air Tools Compressors

2024-11-18 | Atlas Copco | Sweden | Views 949